Differential pressure sensors are widely used in HVAC applications for filter monitoring through pressure drop or VAV controlling, but through-flow differential pressure sensing technology holds great potential for many more applications with, for example, a pitot tube setup.

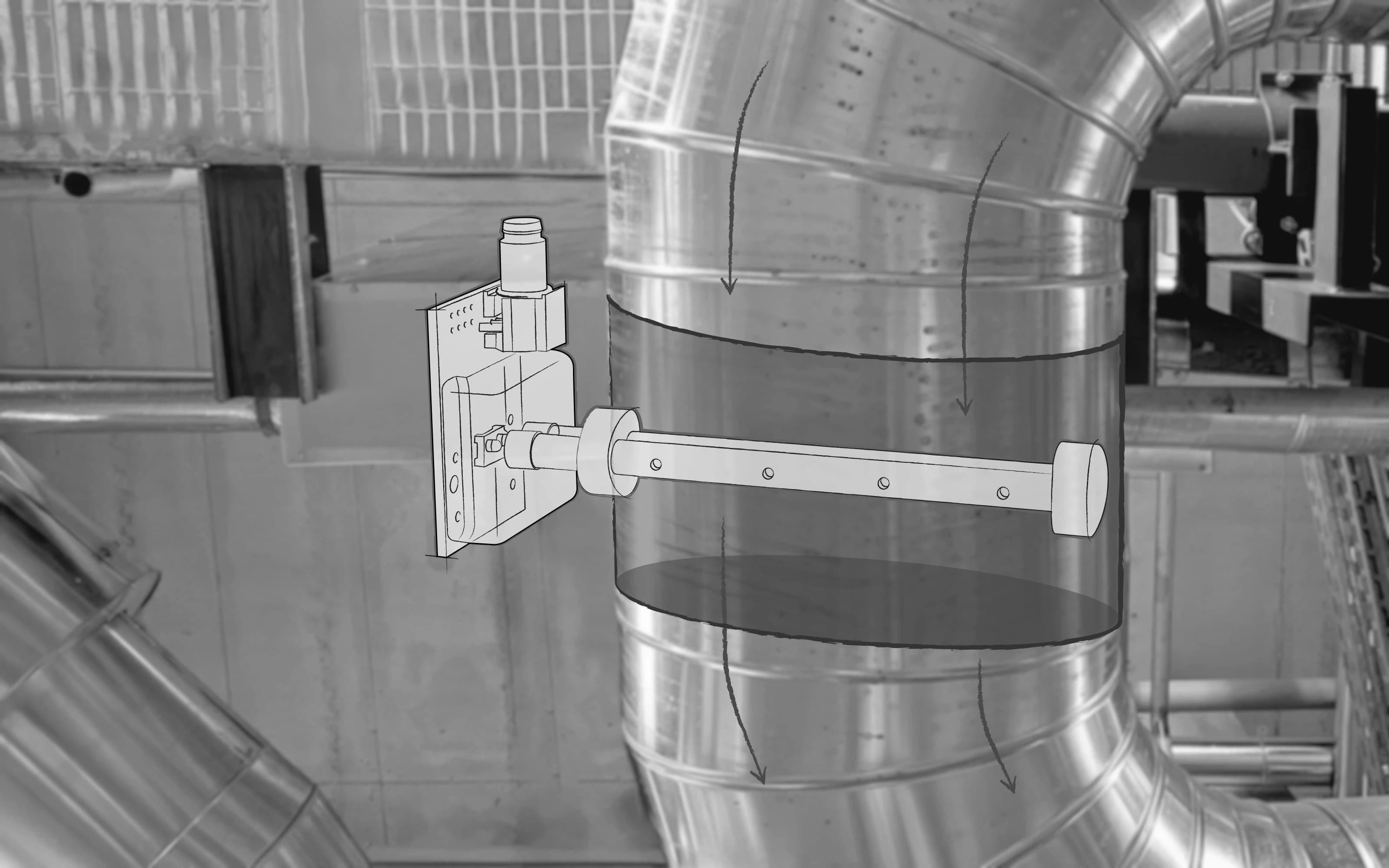

Pitot tube setup for airflow measurement

A pitot tube in combination with our differential pressure sensors allows operators to capture the difference between dynamic pressure and static pressure in an airstream. This difference can be converted into air velocity and mass flow values. In contrast to static differential pressure measurements across components, this method provides a direct indication of the actual airflow in a duct or system, independent of system-specific variations.

Expanded application possibilities

Such an approach opens up monitoring and control possibilities for a wide range of applications, from VAV controls in HVAC systems to filter monitoring in air purification devices, electronics cooling ventilation monitoring and air volume flow measurement for industrial ventilation.

Filter monitoring and predictive maintenance

One particularly valuable use case is filter monitoring: by continuously measuring airflow, a gradual reduction in airflow can be detected, which reliably indicates filter clogging. This enables timely and condition-based maintenance instead of relying solely on predefined intervals.

Airspeed detection in broader contexts

Beyond filter applications, the same principle can be applied wherever accurate airspeed detection is critical—for example, in optimizing fan performance, ensuring uniform air distribution or safeguarding sensitive processes that depend on stable airflow.