Authors: Andries Bosma (Product Manager Gas Flow), Manuel Eckstein (Key Account Manager HVAC)

Where clean air is needed, an air filter is usually not far away. In the last decade, the filtration industry has made tremendous progress in filter technologies. With new materials and designs, advances in nonwoven fabric manufacturing and pleating methods as well as new developments like nanofiber layers and coatings, filters have become more efficient, reliable and compact. Demands on the filtration industry are also changing. It’s no longer solely about filter efficiency and dust-holding capacity; with soaring energy prices and increasing awareness of sustainability, filter media are expected to contribute to lower energy consumption.

Potential and limits of air filtration

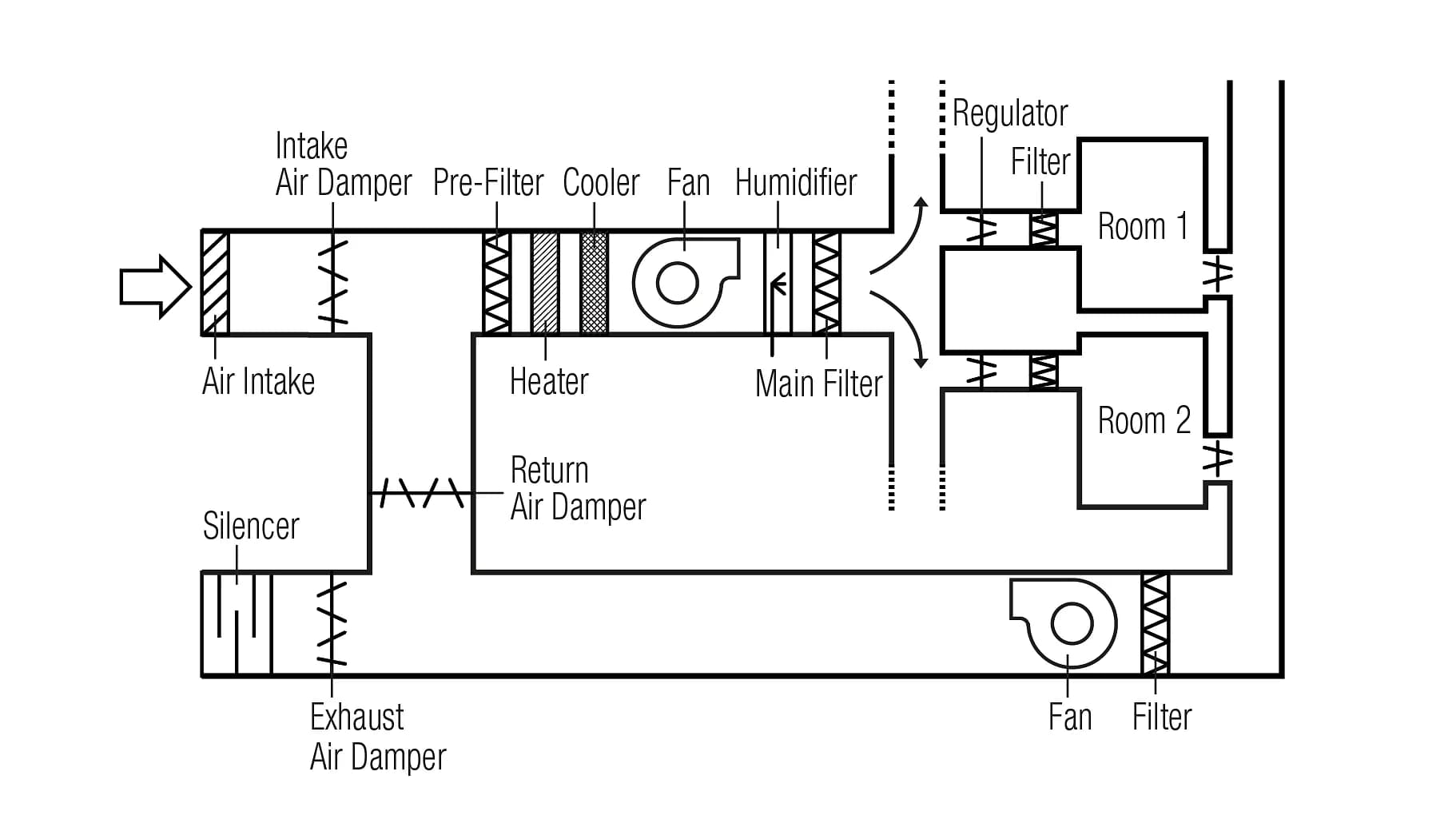

Filters are used in numerous industries and applications all around us. Automotive “air induction system” (AIS) filters protect the engine and the mass airflow sensors (MAFS) against contaminants, while cabin air filters provide clean and healthy air for the driver and passengers. In medical technology, filters purify and decontaminate air in respiratory equipment to increase the patient’s safety. Filters also sterilize air in aseptic packaging processes for food and pharmaceuticals and ensure a good indoor environment in the heating, ventilation and air conditioning (HVAC) industry or support clean combustion in gas boiler appliances. Only a few months ago, the World Health Organization (WHO) released a new report on urban ambient air pollution stating that more than 80% of people living in urban areas are exposed to air quality levels that exceed the WHO’s limits. Air filtration technology will play a crucial role in reducing this percentage in the future.

Each filter can only provide good functionality as long as it is undamaged and its pores remain unclogged. Filters should be replaced regularly to ensure economical, safe and adequate operation. Clogged filters can lead to an undersupply of air, substantial loss of energy efficiency, noisy fan operations, reduced filter performance and, eventually, result in damage to the filter itself. Dirty and humid filters can be a breeding ground for mold and bacteria, punctured filters can be outright dangerous in medical respiratory equipment and a clogged filter simply reduces performance and increases the wear and fuel consumption of an automotive engine. It is therefore important to monitor the condition of a filter and replace it in due time.

Condition-based maintenance

While air quality management and filter technology have made great progress, filter monitoring has largely remained in stasis. For the most part, filters are still changed according to fixed replacement schedules, as a result of visual inspections by service technicians or based on rudimentary differential pressure switches. The reality is that, in most instances, filters are changed too late, resulting not only in reduced safety, energy efficiency and performance of the application in question, but also in a significant loss of business opportunity for filter manufacturers.

In the last few years, an increasing shift from preventive to condition-based maintenance (CBM) has taken place in the manufacturing industry. Sensors observe the state of different parts and maintenance is only performed when certain indicators show signs of decreasing performance or upcoming failure. This trend will help the filter industry to introduce and commercialize new filter monitoring technologies.

Technologies used

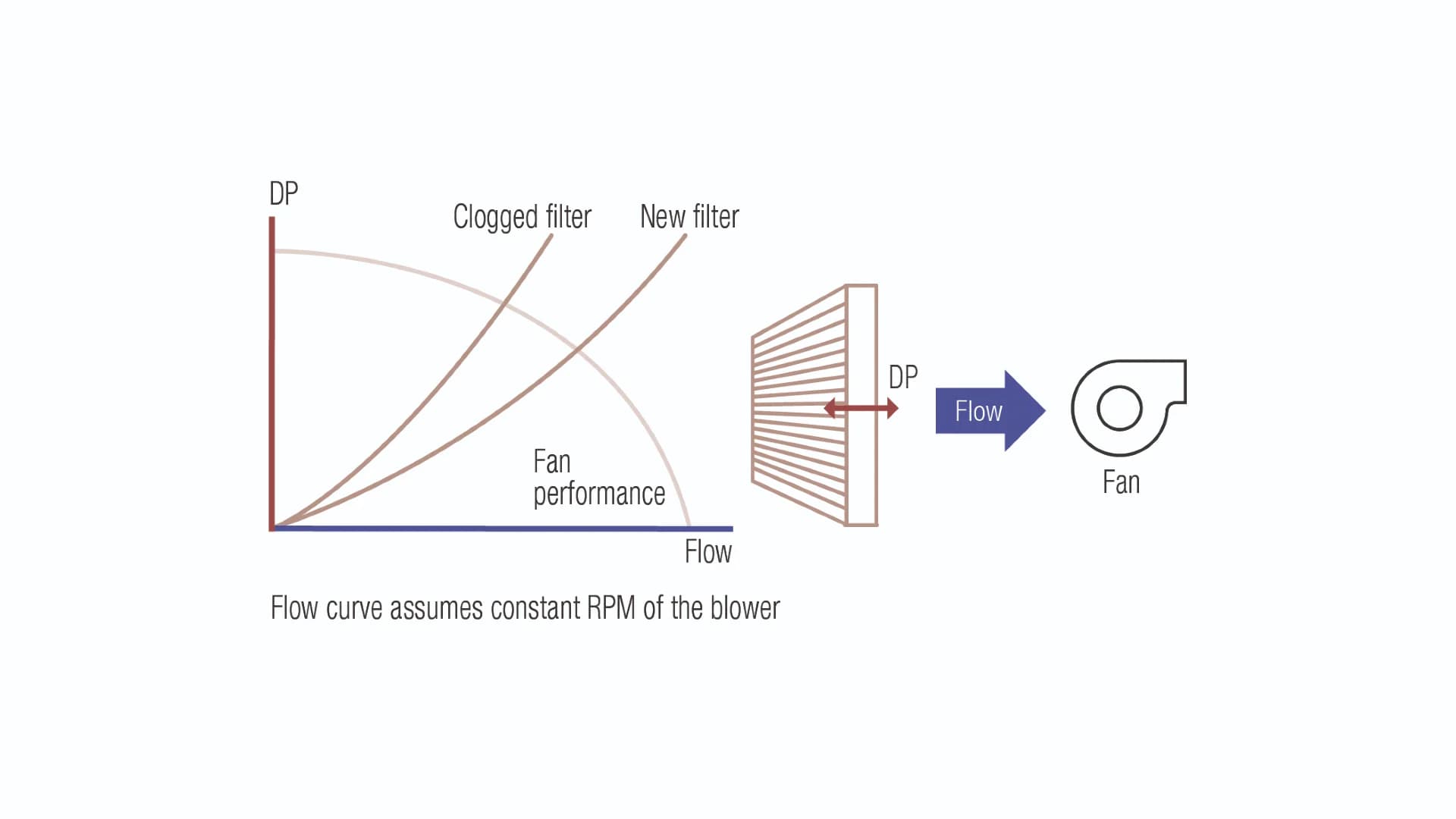

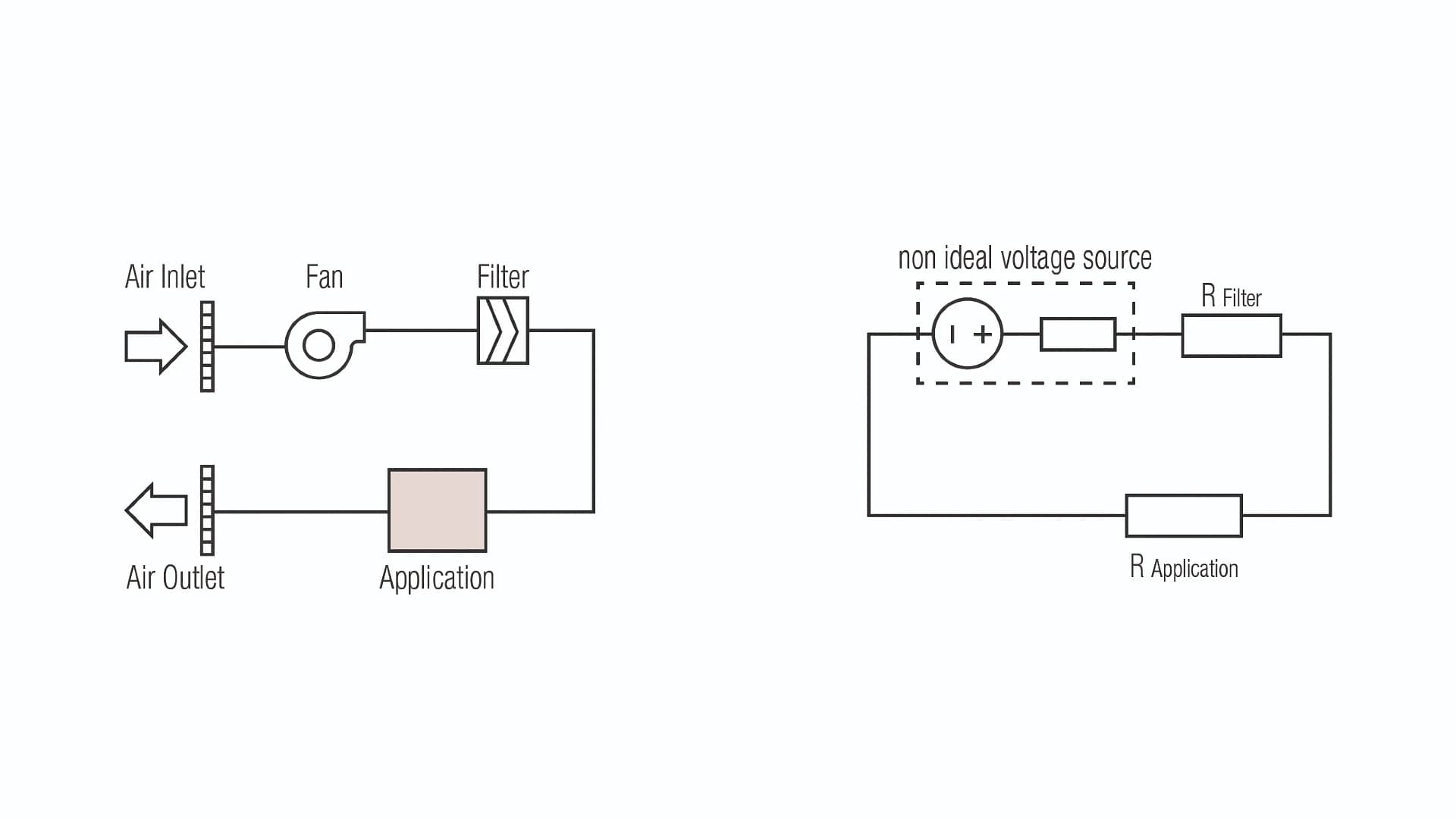

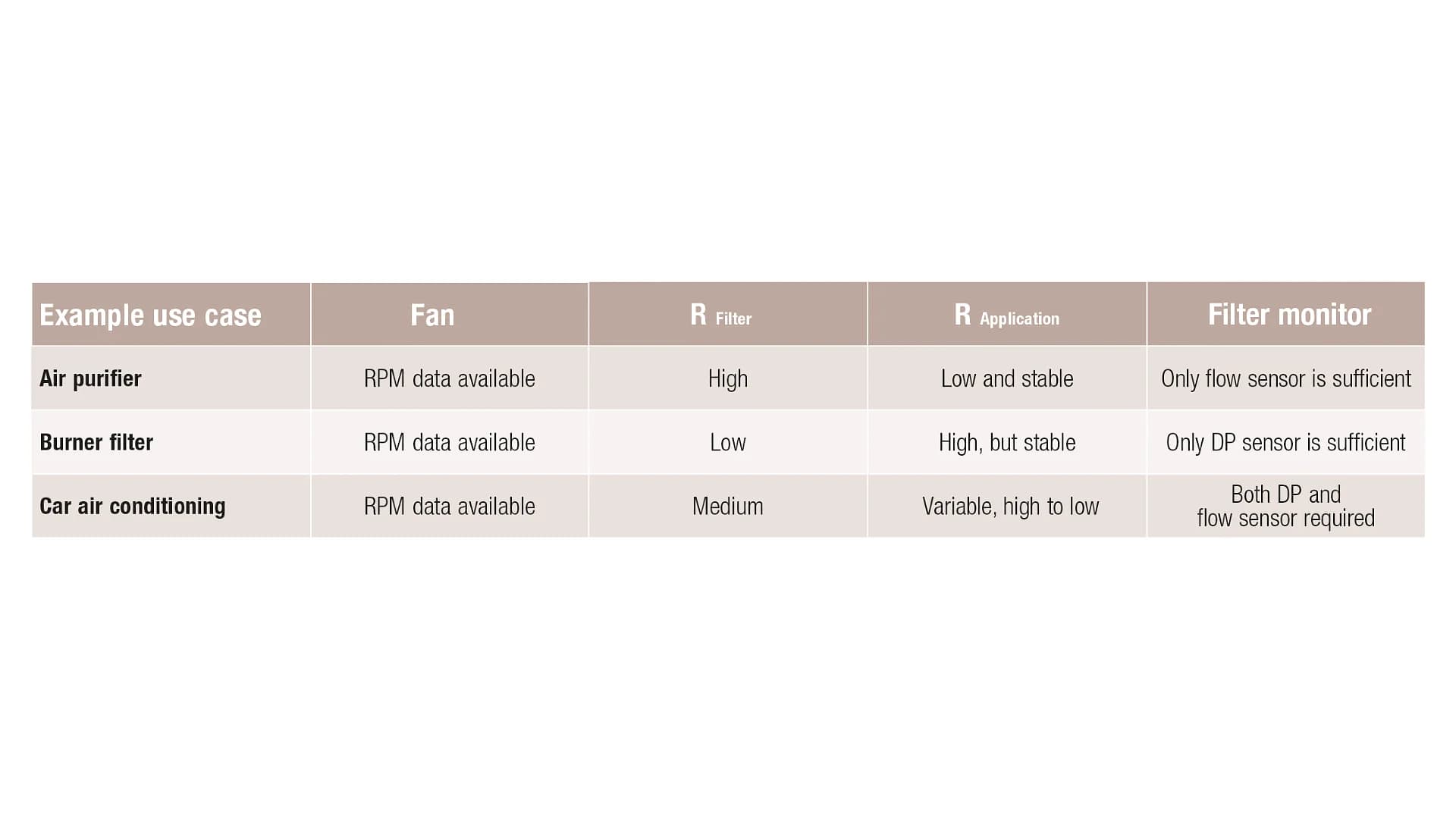

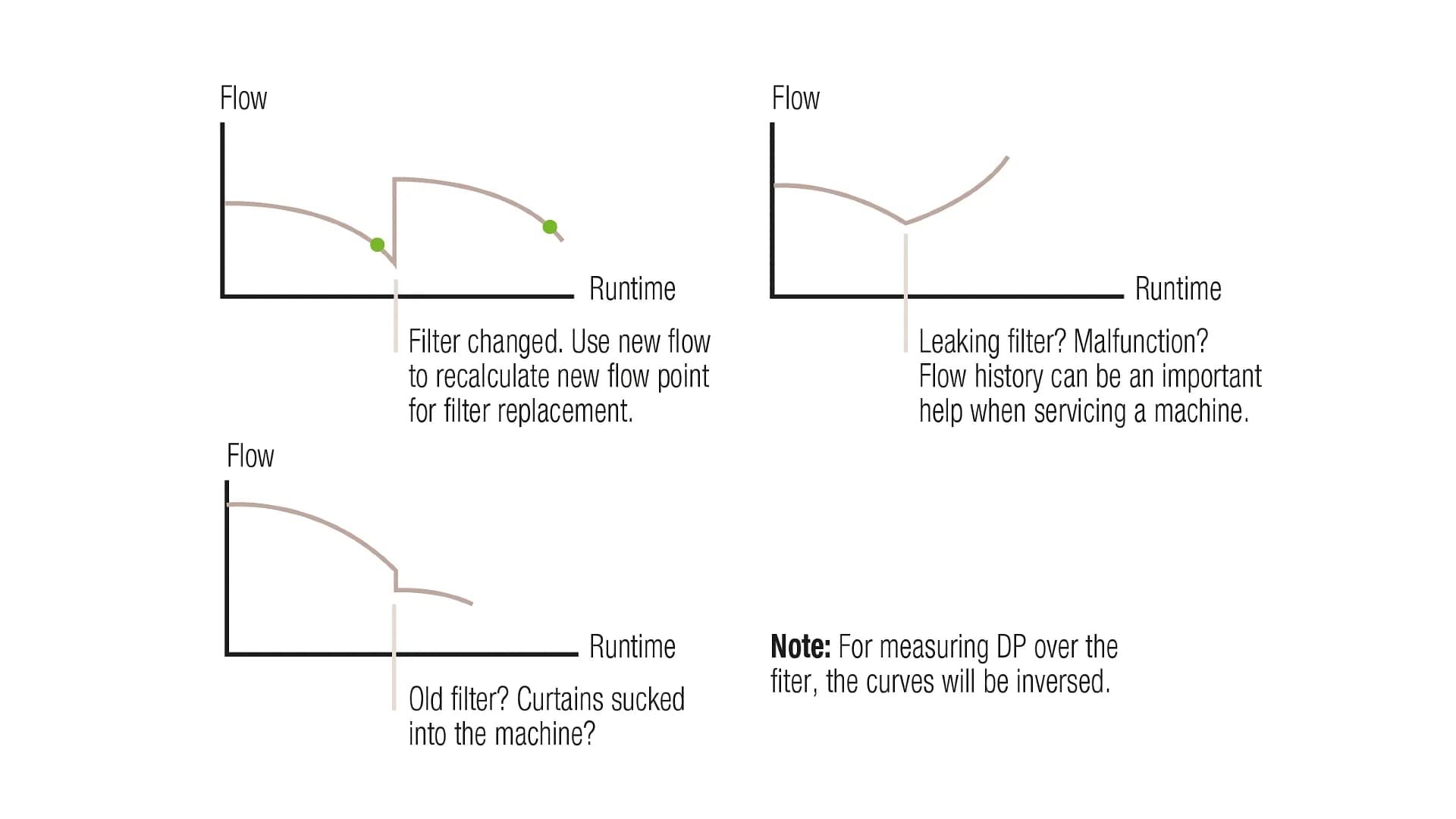

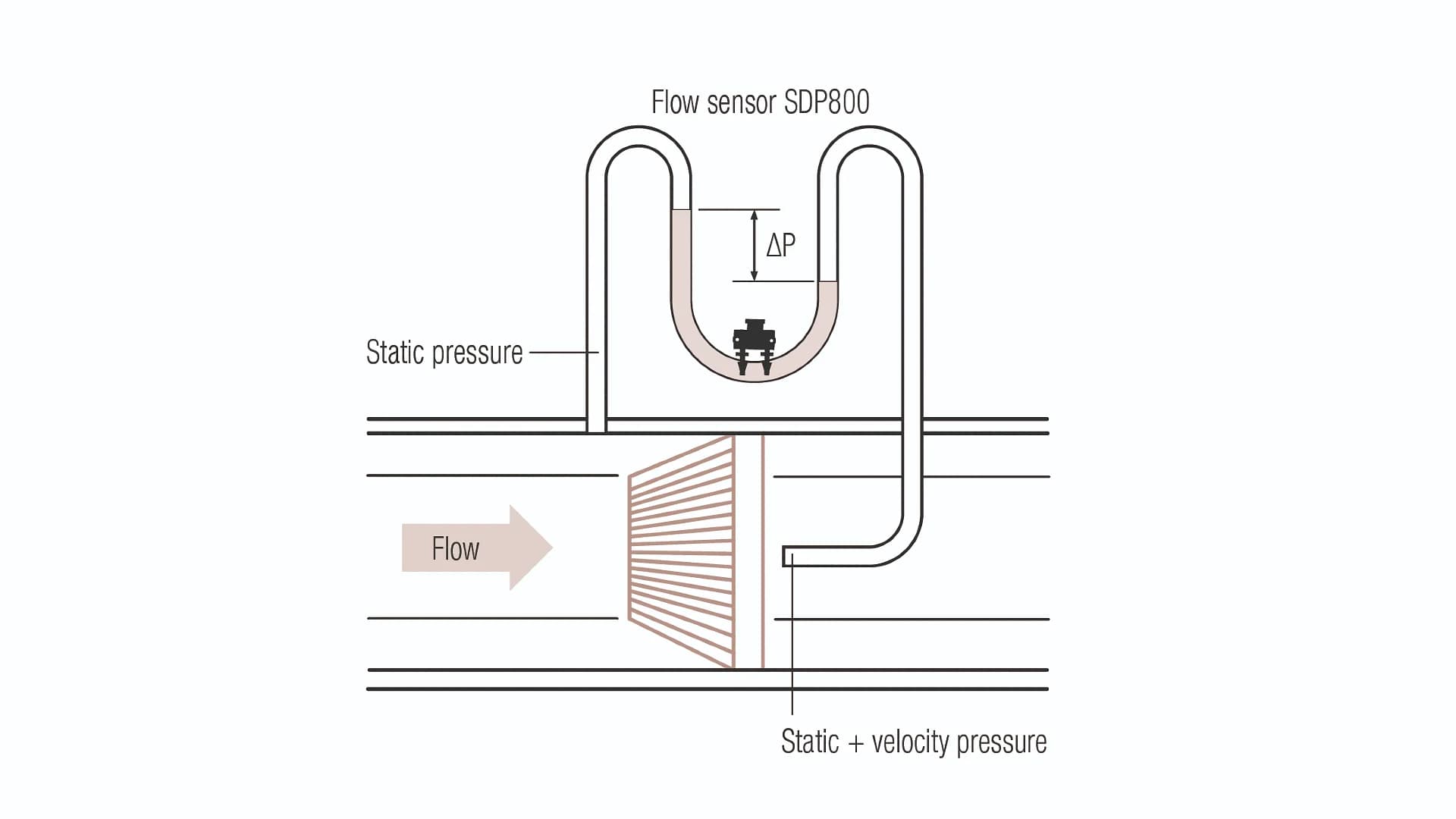

When a filter starts clogging, its resistance to the air flow increases. In systems where the airflow is kept at a constant level, this leads to a rise in the differential pressure across the filter bank. However, fans often begin to propel less air as the filter becomes impeded, so we are really talking about a changing airflow as a filter progresses from a clean to an obstructed state.