Front opening unified pods (FOUP)

Important tool for storing semiconductor chips and an integral part of the cleanroom environment

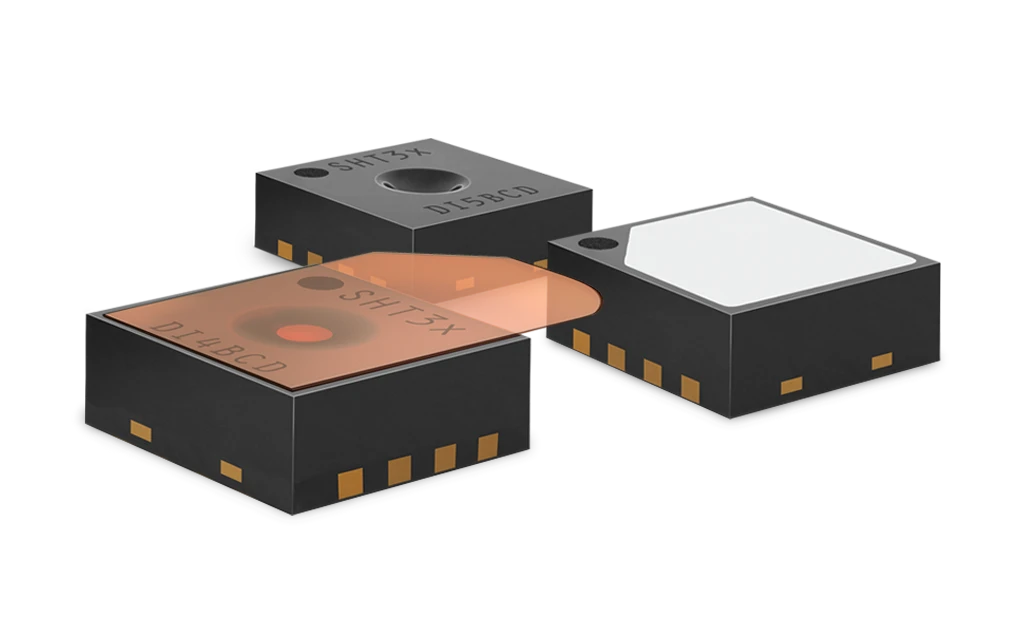

How our sensors make a difference

Precise environment control

FOUPs are purged and filled with nitrogen to provide a controlled environment in which wafers are stored. Other gases can also be injected for pre-treatment steps in finer structures (e.g GAA and 3 nm nodes)

Real-time monitoring

FOUPs continuously monitor parameters such as humidity, oxygen and AMCs (airborne molecular contaminants) to avoid particle deposition and oxidation on the surface of wafers

Safe transport and handling through automation

Automation ensures that the wafers reach the individual cleanroom tools safely. At the same time, the risks of incorrect handling are minimized. This ultimately increases throughput by optimizing the manufacturing processes.