ControlCenter

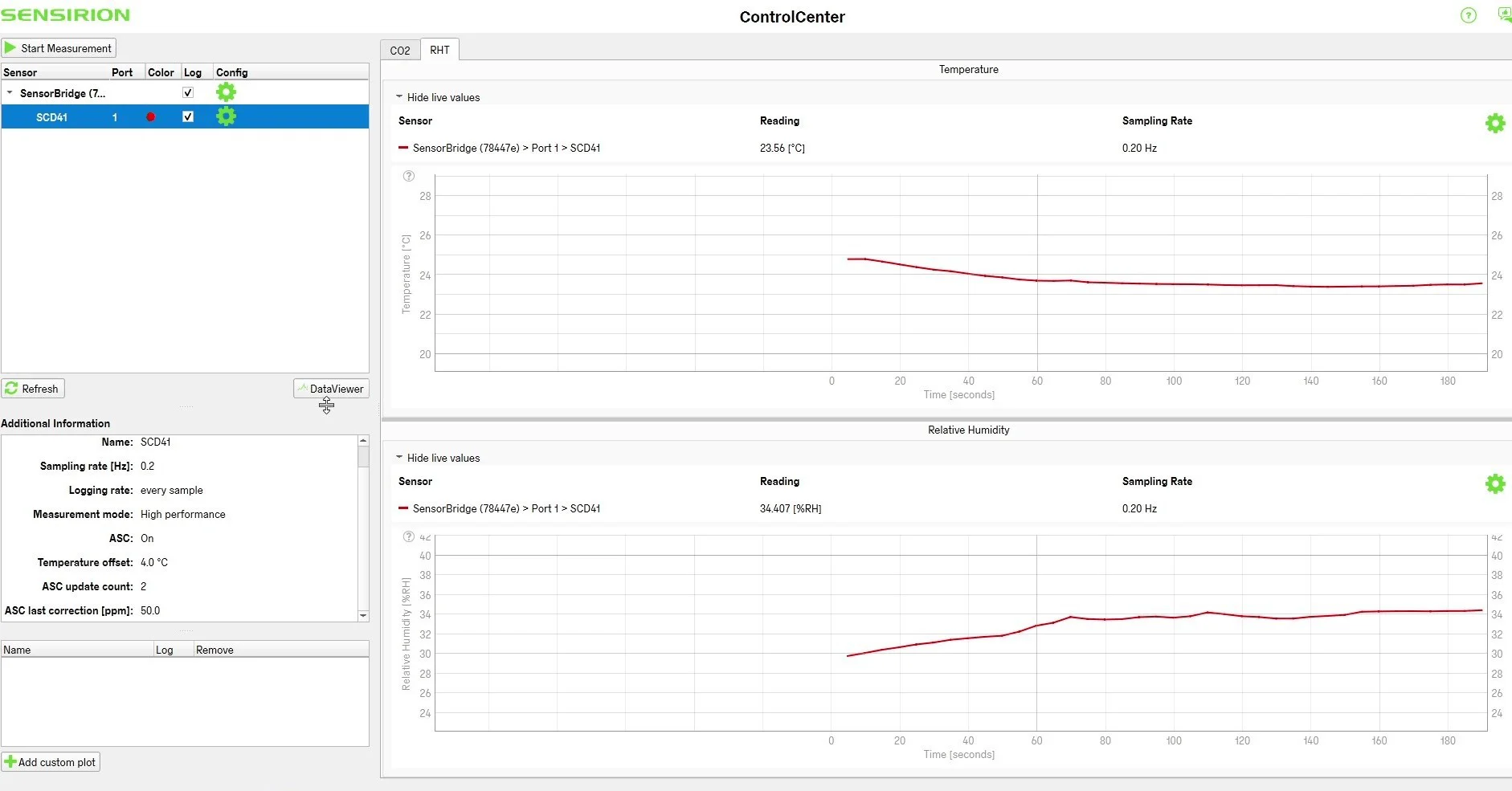

Start your evaluation journey with ControlCenter – the all-in-one solution for most of our sensors.

Version 1.42.0

Download ControlCenter The SEK-ControlCenter viewer software makes it possible to display and log the sensor signals for multiple sensors connected to several SEK-SensorBridges on the same PC. Please find the latest versions through the links below. Release date: 06/2024

| SEK-ControlCenter | Windows 10 | 05/2023 | Link | ||

| SEK-ControlCenter | macOS | 05/2023 | Link | ||

| SEK-ControlCenter | Ubuntu, 20.04 | 05/2023 | Link | ||

| SEK-ControlCenter | Ubuntu, 22.04 | 05/2023 | Link | ||

| SEK-ControlCenter | Windows 10 | China | 05/2023 | Link | ||

| SEK-ControlCenter | macOS | China | 05/2023 | Link | ||

| SEK-ControlCenter | Ubuntu, 20.04 | China | 05/2023 | Link | ||

| SEK-ControlCenter | Ubuntu, 22.04 | China | 05/2023 | Link |