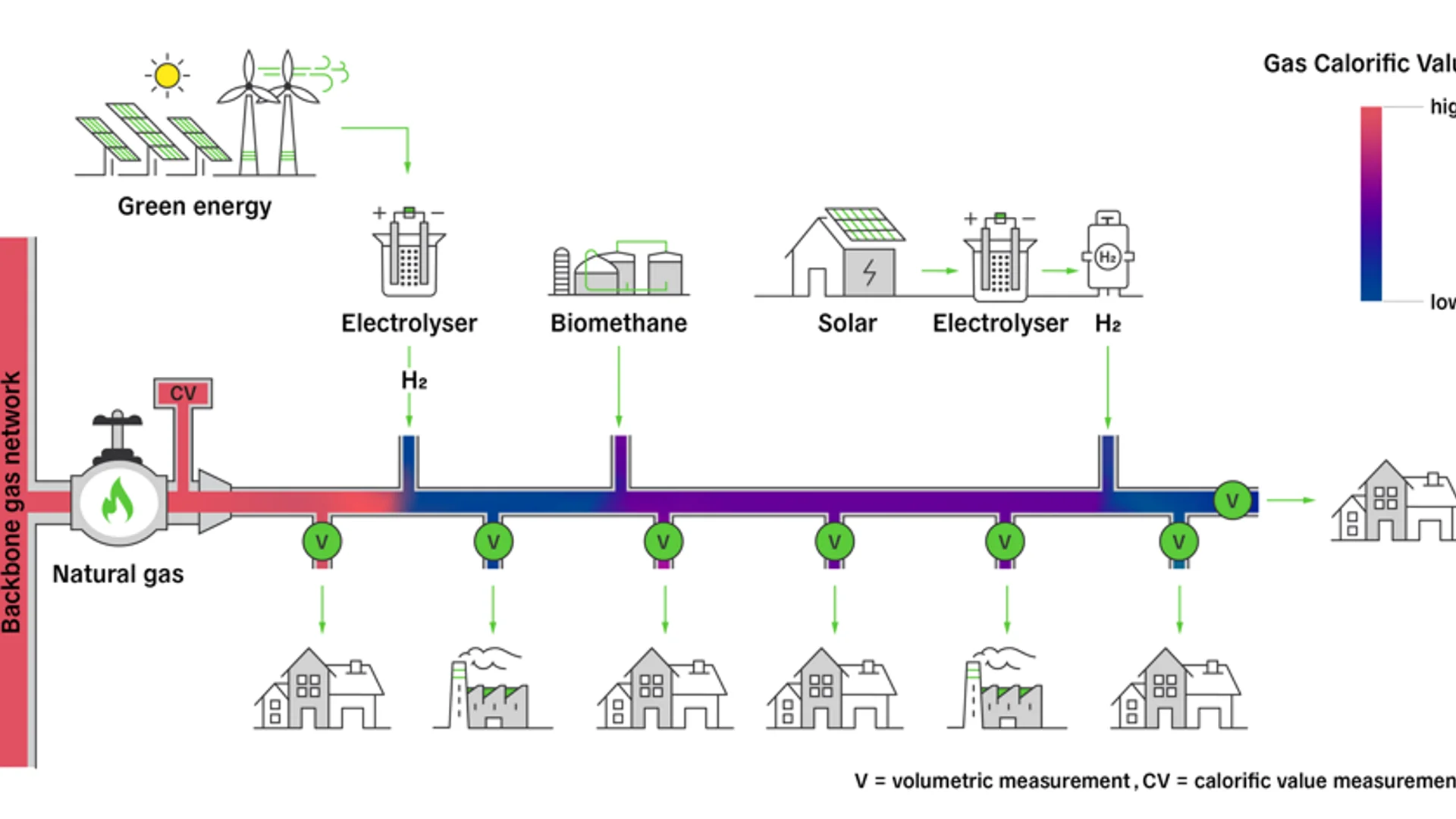

Calorific value: fiscal measurement in the multi-gas era

Related sensors

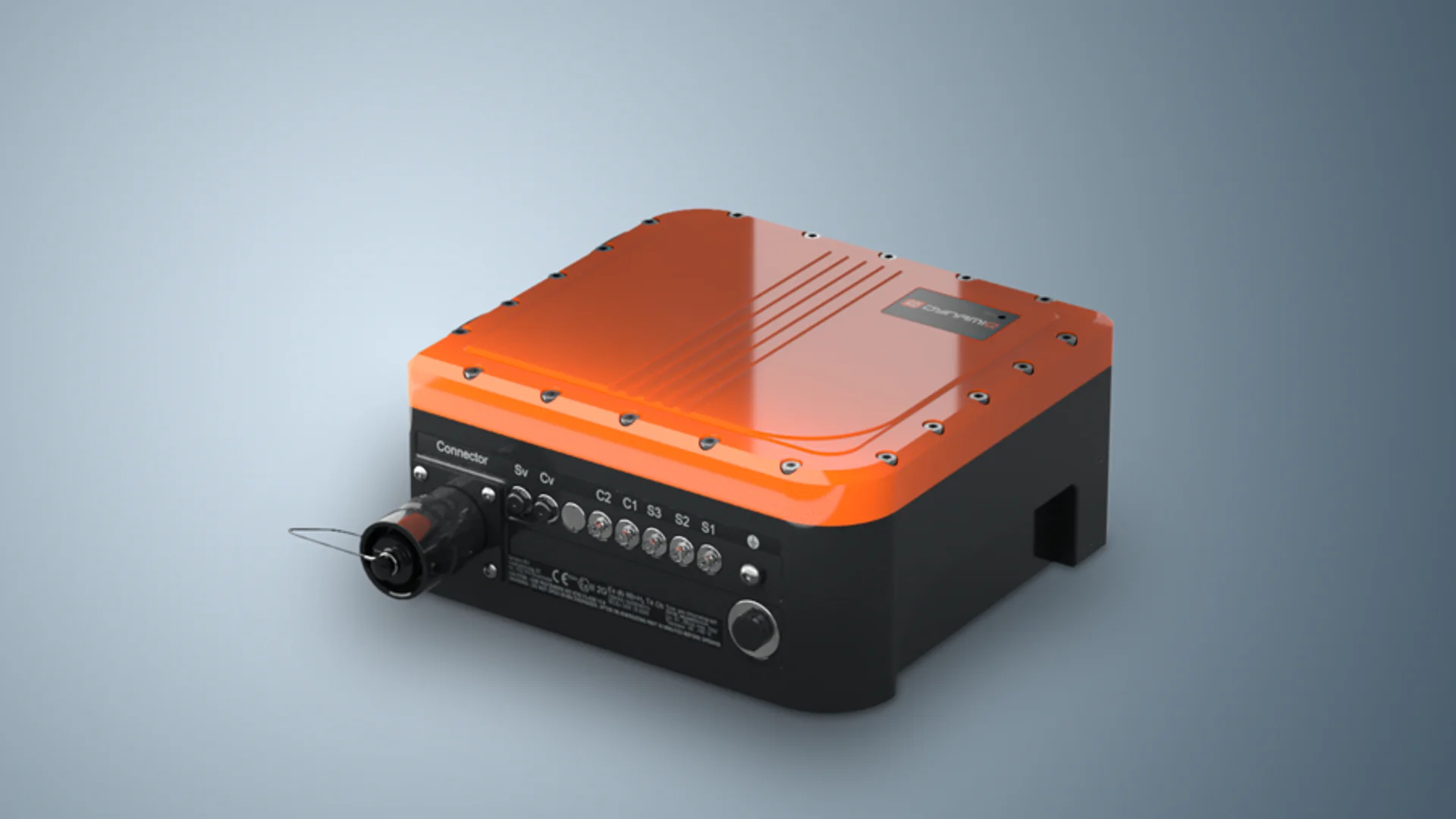

DynamiQ-X

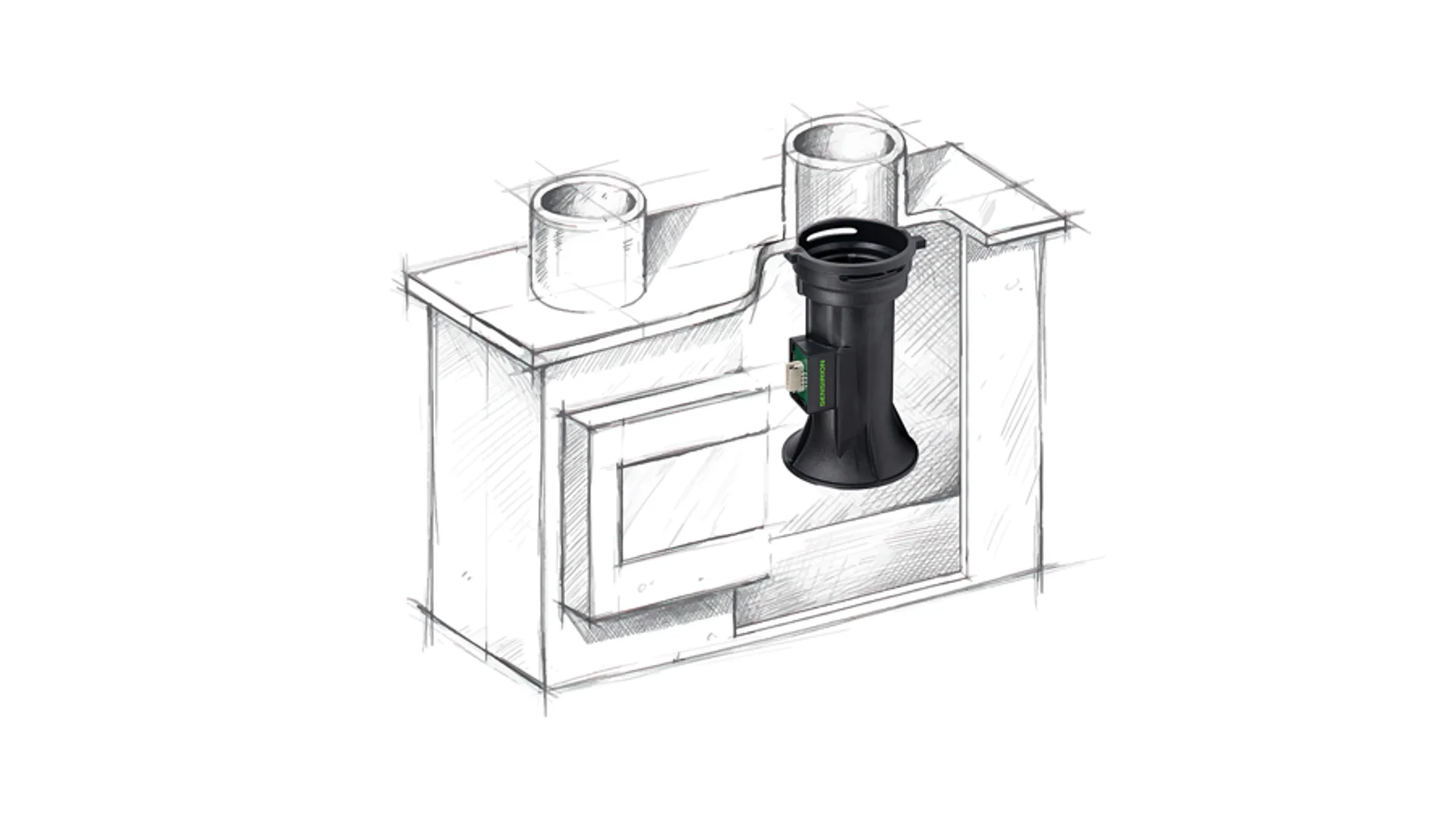

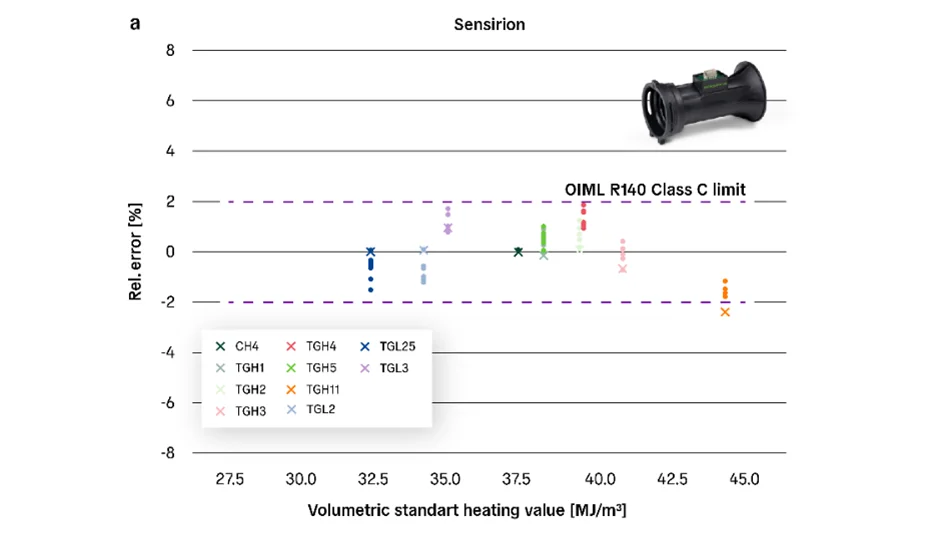

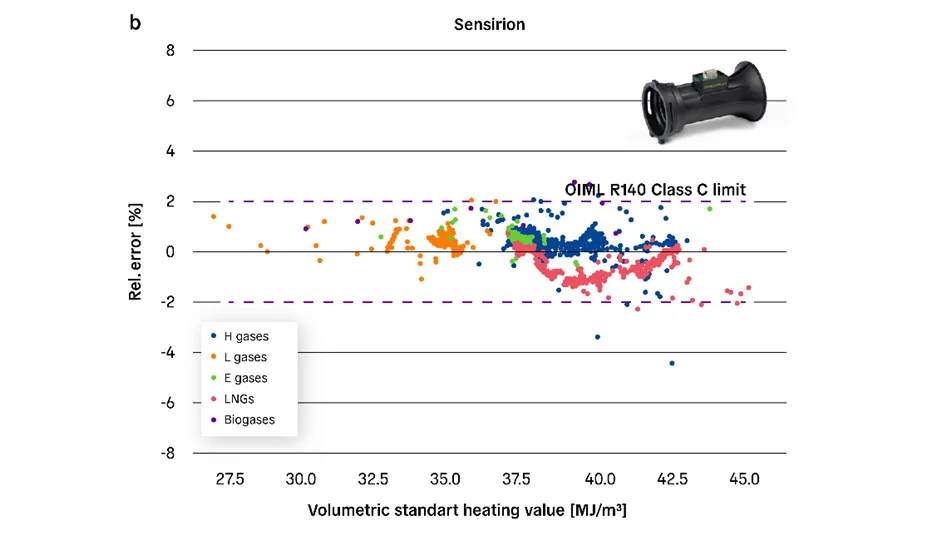

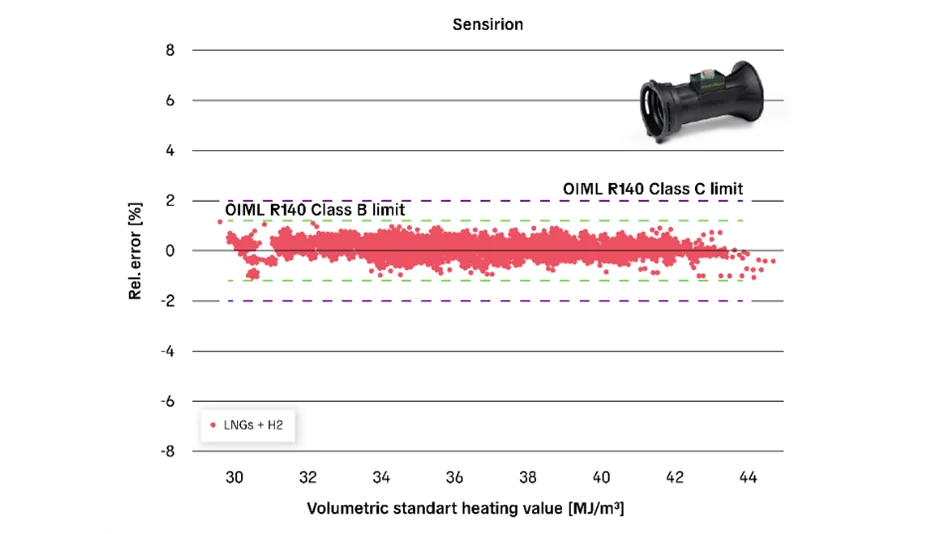

Qmicro by Sensirion

DynamiQ-X

Compact Ex certified process GC analyzer – the micro-gas chromatograph is designed for continuous gas mixture monitoring in industrial process and factory automation applications.