Energy metering

The future of gas metering, as natural gas is gradually replaced with hydrogen and biomethane

How natural gas consumers can be overbilled for energy usage

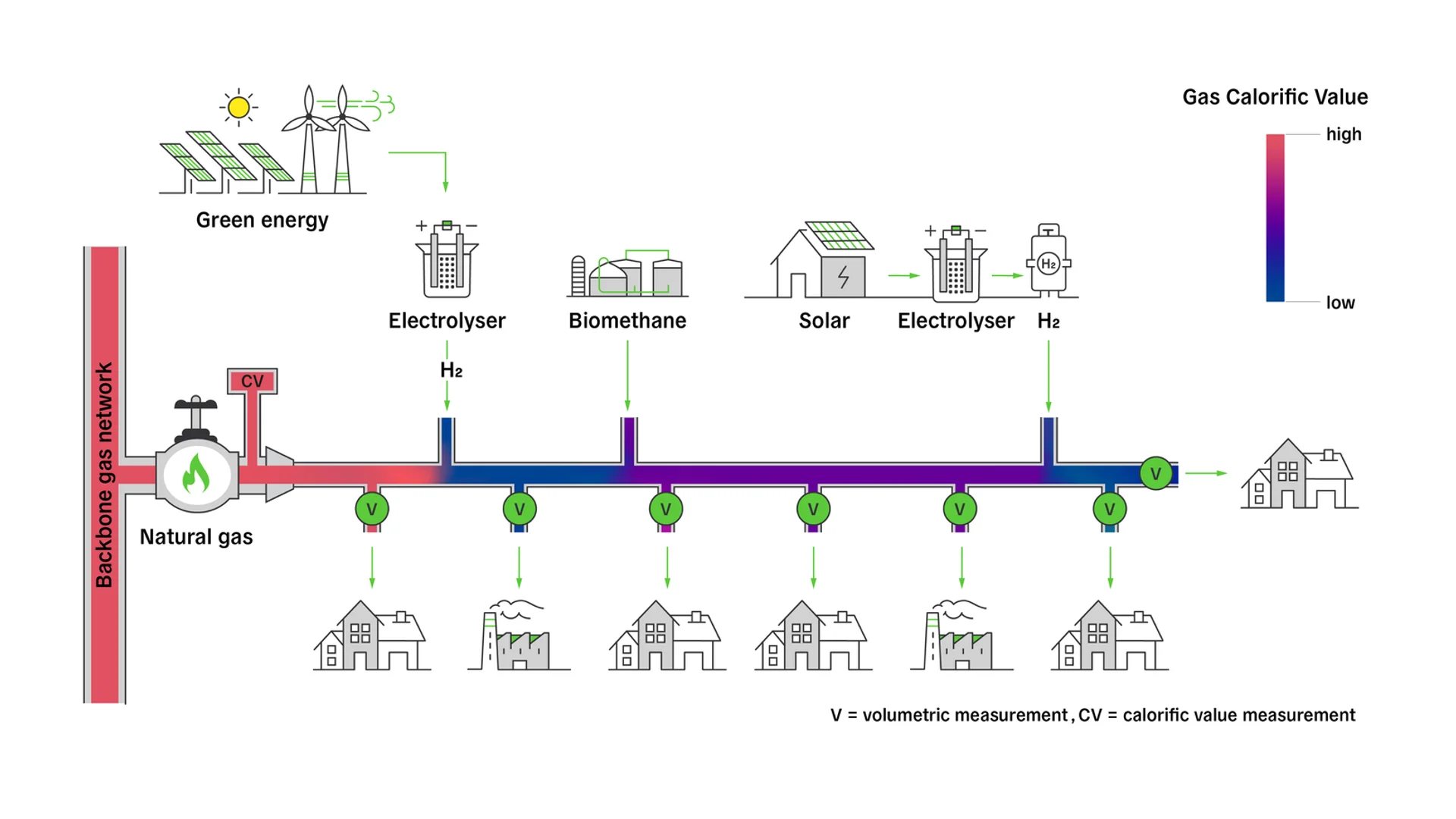

Introduction of biomethane and hydrogen into the grid decentralizes gas injection and leads to increased variability in the calorific value of the gas. According to a recent study, users close to biomethane injection points are already overbilled by up to 6% for their consumption, due to the lower calorific value of the gas they receive.

Webinar

Webinar On-Demand: Thermal-mass gas metering: Proven for years, certified for the future

Konrad Domanski, Product Manager for gas flow systems

Webinar

Webinar On-Demand: Ready for hydrogen with Sensirion

Michele Montinaro, Market Manager for Smart Energy

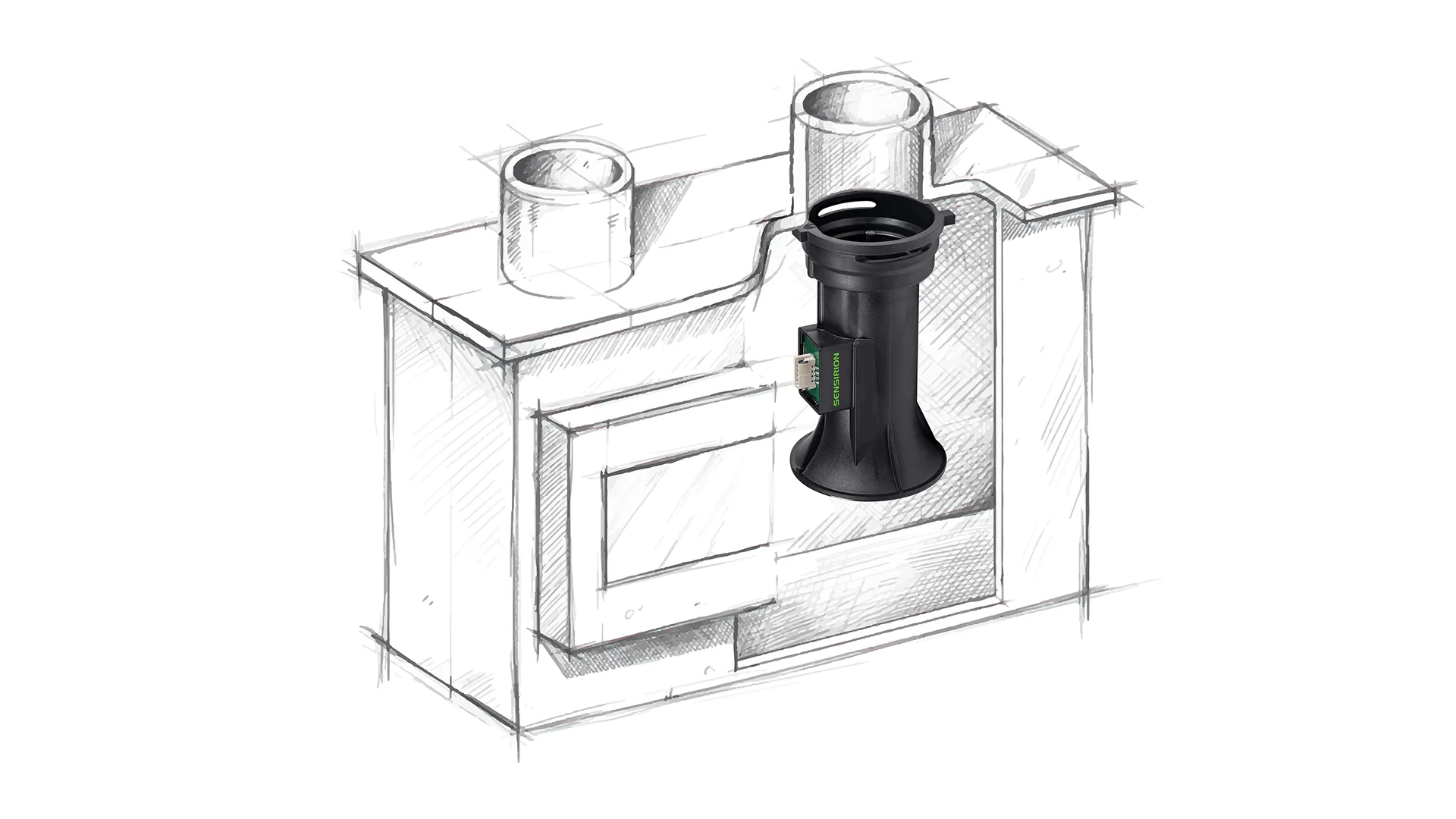

Monitoring gas composition: our sensor solutions

QMicro by Sensirion

DynamiQ-X

Compact Ex certified process GC analyzer – the micro-gas chromatograph is designed for continuous gas mixture monitoring in industrial process and factory automation applications.